We overviewed the scope of work to be performed Summer/Fall 2001

The scope of work was very large on this project. It basically consisted of about a 75% tear down and rebuilt. So all mechanical equipment had to be fixed virtually and the boat needed an entire painting job because various areas of the paint were failing. After getting the costs for all this quoted, a scaled back project was required and my personal scope of work increased significantly.

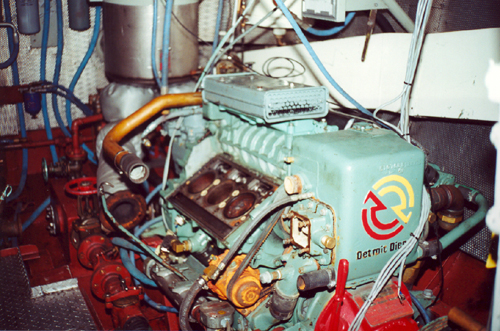

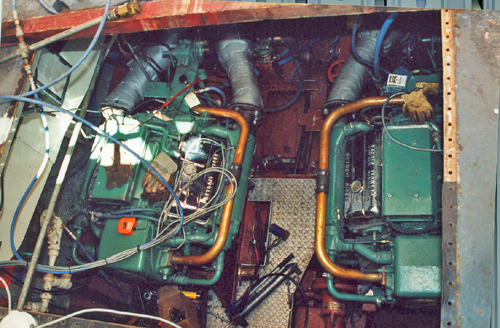

The first step in evaluating what type of project we were in for was to call Detroit Diesel and have a service technician drive up to the Soo and look over the 6-53 engines to see if they were even salvageable. After an evaluation, the service technician determined that they could be saved, but it would be a lot of work. They could not work on them in place though, so we had to remove the engines and get them to an engine repair place. They were removed with the help of the yard and they went back to Detroit Diesel for further evaluation and repair. In order to get them out of the boat, the protective screen, mast, helmsmen’s chair had to be removed, the deck grating in the pilot house area and then finally, about 250 small bolts holding the large watertight steel engine plate covering on the deck. All of the electrical wires were removed and tagged for what they went to and all hard piped plumbing were disconnected and a crane lifted the engines out.

Port engine was partially tore down. Rust had set in pretty heavily in the open engine block.

The tarp is protecting the open engine compartment. The protective cage, coxswains chair and decking has been removed.

The engines are returned from Detroit Diesel and ready to be driven back up to the Soo.

With the engine hatch cover removed, this is what you see. This is after the engines were re-installed.

This engine work was started in the fall of 2001 and the engines were completed in the spring of 2002. They were taken back to the shipyard to await installation when the weather started to clear up. Being in the UP of Michigan, winter last a little longer up there. A few smaller things were done in 2001 such as researching where all the components that were either missing, damaged or needing repair were made or sold. Part of the research involved contacting the US Coast Guard Yard, The National Motor Lifeboat School and a few local Coast Guard stations that these boats were still in service at to see how things were put together. Various internet research revealed a portion of the manuals, boat outfit lists and sea trial information was available online from the US Coast Guard. This helped a great deal. Luckily, I was able to acquire a full set of manuals for this boat, including drawings of the original boats when they were built. As with all things, advancements in communications and other requirements changed the boat over time as it was updated.

So after getting these manuals, a whole big box full, things fell into place more. For example, the windshield wiper mechanism was broken and needed replacement. The windshield wiper is air powered and the retailer was found that carried it and it was replaced. Without the manuals, the restoration would have taken a much longer time. So some of the things that could be ordered that we knew about, were, and shipped to the yard.

Major work begins in the Spring of 2002, follow the timeline section to see how the work progressed.June 2002 update:

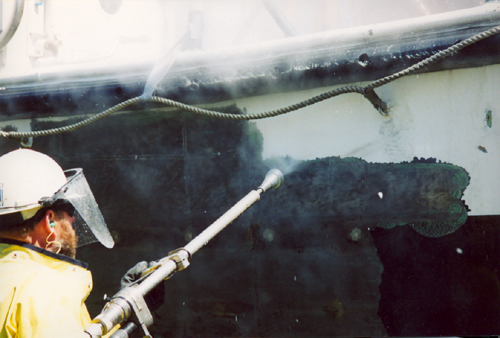

44376 has been completely stripped of paint using ultra-high pressure water jetting equipment supplied by NLB Corporation in Wixom, Michigan. 40,000 psi water jets removed all the paint on the hull and superstructure for recoating. For more information on water jetting please view NLB's website at www.nlbcorp.com and review the surface preparation section of the site. Water jetting is the best way to remove paint from ships and lighthouse structures for recoating and this superior method was used in this restoration.

Water jetting is the only proven method to remove salts and other contaminants on a steel structure. Water jetting gets into all the peaks and valley’s in a steel profile, unlike sand blasting, which knocks over those peaks and traps rust and salts in the valley portion of the steel. This will lead to premature failure of the paint coating system because the surface was not as clean as it could be.

The engines have been completely refurbished and placed back in the engine room. The hydraulic steering ram, which had been removed, was placed back into position and then had to be modified to work with the existing hardware. A few missing items are still being sought after currently that were robbed off the boat when she was decommissioned. 70% of all the mechanical work has been completed at this time. Electronics need to also be purchased. Painting of the hull should be done any day now. The estimated completion time is now the end of 2002.

Initial blasting tests. The green paint in the partially blasted box indicates it is the zinc primer base coat. We found that if we wanted to leave this layer on we could using the water jets. Since the coatings were old, we decided to remove the entire coating 100%.

Mid section being blasted, stripping 100%. Below is a close up photo. Notice how 100% of the coating is being removed.

The main reason the hull coating had to be removed and as you can see from this photo of the bow anti-skid deck, it is flaking off badly and rust had started in many areas under the flaking where the coating had failed.

This is after day one of blasting. This is what is called Flash Rust. This happens when you use water jetting a lot of the time, not all the time. Coating manufacturers make marine paint to go over flash rust. It actually helps the paint bond to the steel surface and will not effect the coating. Some manufacturers of marine paint will warranty a paint job longer with a water jet prepared surface compared to a sand blasted surface.

Working to remove the paint off the turtle back.

March 2003 Update:

44376 has been mechanically completed. A few minor items will be finished once the weather breaks. The electronics are still needed and will be sought after in the very near future. The photos of the water blasting have been added and as you can see she was completely stripped. A new paint job has been applied and she is looking good. New photos have been added of the new paint job she now has. The ice conditions prevent her launching right now to actually start testing the engines, steering and other systems. It is predicted that at the end of April we may be able to put her in the water if all goes well with the weather. The boat is looking real good right now. New photos were taken on March 20th, 2003.

Sea trials will begin in the spring, probably around the end of April. She will have at least three weekends of full running to make sure everything is working properly. Once all the bugs are worked out we will see where she goes next. Most likely to start with visiting lighthouses in and around the St. Mary's River. She will be taken out into Lake Superior for a small journey as well. She will visit some former lighthouse locations there as well. Once it is all done it will start to make its way down Lake Huron visiting offshore crib lights all the way down to Lake Saint Clair.

The boat has been painted and most of the mechanical work has been completed. She is ready to be set back in the water to make sure she floats and to start testing the engines since they can't be tested on land being water cooled engines.

May 2003 Update:

44376 is scheduled to drop in the water on June 9th. For the following two weeks after that she will undertake sea trials to make sure everything is okay. The yard will then turn her over for general use after that.

July 2003 Update:

44376 is in the water and as all projects go, delays in fixing things cause slow downs. After extensive wire tracing and making sure everything was hooked up correctly, the engines were started in her for the first time. After three days of straight work things started slowly coming together. Other issues came up such as the throttle cables not being hooked up and were bent, wires that were hooked up to the wrong locations, buttons not working and the list goes on. The canvas dodger to protect the pilot area from in-climate weather was fitted up to make sure it would go on. About 50% of the dodger was on and then off again to prevent it from getting dirty. Some extra parts were needed to get the rest of it on.

It looks like by mid-July we will have it running 100%. A few tweaks will be needed along the way. I'm keeping my fingers crossed.

44376 Floats! Final mechanical work, then engine testing to go.

July 25th to the 28th 2003 Update:

44376 has made it to its new home on Harsens Island on Lake St. Clair over a four day trip down from the Soo. More tweaking is necessary after this long run in. Luckily they are all minor adjustments.

Home at Harsens Island, MI. after a four day trip down from the Soo.

October 2003 Update:

44376 was scheduled to come out of the water for the year and was on the way to the boat yard when an engine failure occurred. The port engine had a raw water pump failure that caused the engine to overheat. Also at the time, the main thrust bearing was discovered to have spun on the crankshaft at some point. This was discovered after the overheat inspection when the engine was dismantled. The damage to the thrust bearing had been happening since day one when the engine was put back in service and luckily this was a warranty issue to get the engine fixed. The thrust bearing failure caused the entire engine to need to be replaced.

July 2004 Update:

44376 has had the port engine entirely replaced because of the damage. The pilot station of the boat had to be removed and the engine covered removed to get the engine out and the new one put in. Everything was reassembled and put back together. Sea trials were completed on two different occasions, again to make sure everything was shipshape. She is again able to traverse the waters of the Great Lakes.

2005 Update:

After missing most of the year last year with the engine problem, this was the first full year of the boat operating. Not many changes occurred and the boat ran great and made several trips up the St. Clair River and down the Detroit River. Some minor equipment was added such as a stokes liter basket for lifting victims up into the helicopter and three cold weather exposure suits were put on the boat.

2006 Update:

Some more minor upgrades were done this year. The boat poles were made from wood and the brass hooks put on the ends and they are mounted to the side of the boat in the leather straps. A pump can that carries the portable dewatering pumps was purchased and a pump can cover was purchased for it. New stickers were made for the Fire Pump Main, Fuel Vent and Fuel Fill locations on the boat. The boat was taken out of the water at the end of September and the dodger removed to repair the Velcro straps.

On September 9th, 2006, the Great Lakes Lighthouse Keepers toured 44376 as part of the Blue Water Beacons cruise they put on. Approximately 80 visitors toured the boat in which most of them have never seen one close up before. This was the boat first formal scheduled tour. Other visits have been shorter and with very small groups of people.

Ongoing maintenance items still exist and other parts and repairs need to be done. Boats are always constant maintenance. Most of the things are little things and can be done over time. These were great boats that served the US Coast Guard. The one that is still in service is doing the same job it has done for the past 30 plus years. Other boats have been saved, others have other uses in towing and salvage and a few are museum displays. The bottom line these are boats built to last and they heroically served our country and saved many lives.

View the former Coast Guard boat in the Soo before it was purchased along with other photos of restoration activity in the photo gallery section.

©copyright 2006-2010